As the name suggests, an automatic bottle filling machine works with a special mechanism to fill liquids within bottles in succession. It has a wide range of applications like soft-drink, alcoholic drink and pharmaceutical industries. A bottle filling machine is available in various types, each with their unique capabilities and filling rates.

Here are some tips you should follow when buying a bottle filling machine:

- Check if the equipment quality is good.

- Compare the prices with other dealers to see if it is reasonable.

- See if it satisfies your company’s all needs and wants.

- Check if the equipment is not outdated.

- See if the machine can be further integrated.

Now we shall discuss the 4 quick tips regarding a bottle filling machine.

What type of liquid product do you have?

The main tip regarding the liquid filling machine is to determine and convey the types of liquids you will be filling using it. Depending on the viscosity of your liquid, different types of machines may be needed. For instance:

- Piston fillers may be used for liquids with higher viscosity.

- Gravity fillers may be needed for less viscous liquids. They are generally used in a water filling machine.

Determining the viscosity would help ensure various other things like automation, filling speed and other functional issues.

What type of containers are you filling?

Naturally, most people would want bottle filling machines that offer a lot of flexibility, i.e., they have the ability to fill liquid in various kinds of bottles. However, it would still be a good idea to discuss the specifics of your containers with the dealer or supplies provider.

You should let them know of a few things like:

- The type of material the bottles would be made up of (glass, metal, plastic).

- The shape and volume of the containers.

- Would the containers be stiff or flexible?

- Would the containers require labelling?

- The type of capping method they would require.

Which level of automation do you want?

For a liquid filling machine, the level of automation is the number of bottles that can be filled in a particular amount of time. This is an important thing to consider because depending upon the market demand, you may want to have a high or a low production speed. Let’s say for instance, your production speed is too slow to match the market demand. It would lead to other brands monopolizing or your customers getting anxious.

It should also be worth considering that there is a low chance for the market demand to remain static. As the production process continues, it could increase or decrease depending upon the time of the year. So, you may want a machine that is flexible enough to be automated accordingly. However, there is always a limit to such flexibility.

If you discuss this with your supplier in detail, they may provide you with the suitable machine.

What is your available floor space?

Filling machines may require various kinds of areas to be fitted in properly. If your organization has a very limited floor space, you may not be able to afford a huge bottle filling machine. In that case, you should consult the dealer and tell them about your available floor space, so they can recommend or customize your machine accordingly.

Conclusion

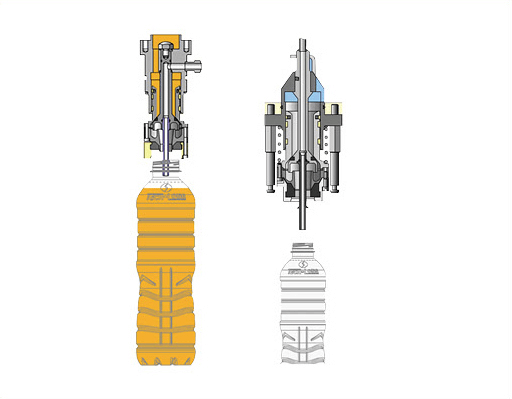

As a leading manufacturer of bottle filling machines, Tech-Long is committed to providing the perfect automation solutions for the new generation of intelligent workshops and factories. Adopted non-contact filling method to ensure the sanitation of the whole filling process, our automatic bottle filling machine is suitable for different types of liquid. At the same time, it can also realize accurate control of the liquid level and simple maintenance. If you want to know more about our bottle filling machine, Tech-Long welcomes the opportunity to cooperate with you.